In compliance with EU personal data protection laws, we are committed to protecting your personal data.

By clicking "Accept All", you allow us to place cookies to enhance your experience on this site, help us analyze site performance and usage, and enable us to deliver relevant marketing content. You can manage your cookie settings below. By clicking "Accept All" you agree to the current settings.

Risk Management

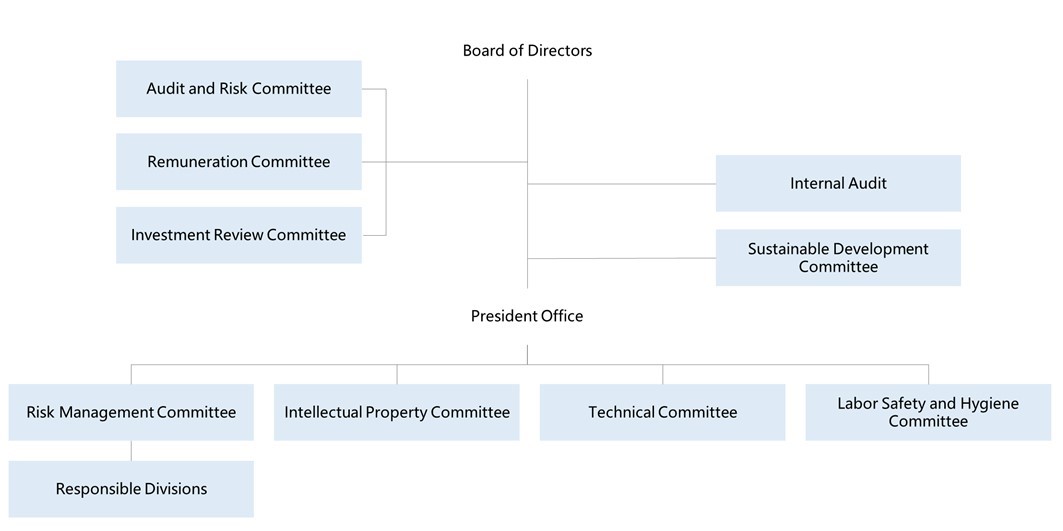

Risk Management Procedure and Organizational Structure

The “Operational Risk Management Regulations” of the Company was approved by the board of directors in 2014. The “Operational Risk Management Regulations” was established in accordance with the structure of the ISO 31000 standard, and such regulations are served as the operational rules for relevant organizations and supervisors at all levels of the Company to perform operational risk management. It was revised on Dec 23, 2024 and approved by the board of directors.

According to the Operational Risk Management Regulations, the Company has established a Risk Management Committee in the organization in order to perform risk identification for all risks from the internal or external of the organization during the operation process that may cause major operational impact, operation interruption to the Company, or may affect the execution of important strategies, affect achievement of important goals, or may cause violation of laws/regulations, etc., and to perform risk identification, risk assessment, risk response and risk supervision operation along with process and detailed rules, thereby minimizing the probability of occurrence and impact of various types of critical operational risks.

The Company has established a Risk Management Committee with the President acting as the chairperson of the Organization in charge of directing the promotion and operation of risk management plans. Under such Organization, there are various center responsible units in charge of the promotion of various affairs and operations of risk management.

Scope of Risk Management

The risk management meetings of the Company are convened by the President regularly and irregularly for matters related to

(1) Business/Laws/Regulations/Standards

(2) Political Environment

(3) Economic/Financial Environment

(4) Climate Change/Natural Disaster

(5) Technology and Information

(6) Competition Environment

(7) Facility/Equipment

(8) Sales/Market Management

(9) Supply Chain

(10) Financial Operation

(11) Community/Environmental Safety and Health

(12) Internal and External Personnel of the Organization, etc.

There are a total of 12 major categories and 92 indicators for assessment, and mitigation responsive strategies, solutions and operation continuity plans are established to eliminate, reduce, transfer and accept risks, in addition to the enhancement of the pre-warning and monitoring capacity, promotion of risk identification and control, in order to implement appropriate risk management oriented business model, thereby achieving the operational goals and increasing values for shareholders and internal/external related parties.

Annual Operational Risk Management Execution Status

The second regular risk management meeting was held in 2025:

2025.04.07 Risk management regular meeting was convened. (US-China trade and technology conflict / US high tariff policy / Domestic production cost increasing)

2025.10.01 Risk management regular meeting was convened. (Precious metals market price increase / increased frequency of natural disasters / competition from other industries)

2025.05.05 and 2025.11.03 The 2025 operational risk management execution status was reported in the board of directors meeting.

| Dimension |

Major Issue |

Risk Identification |

Risk Response |

Countermeasures |

|---|---|---|---|---|

| Corporate Governance |

Sustainability |

US-China technology controls and regional geopolitical conflicts have led to a sustained increase in precious metal prices, resulting in elevated production costs and reduced gross margins. |

Mitigate risk impacts |

1. Continuously advance the 3A1E industry expansion into new markets and customer segments. |

| Environmental |

Climate Change Risk and Opportunities |

The increasing frequency and severity of global natural disasters are having a greater impact on daily life, production, and transportation, thus heightening the risks to the continuous supply and delivery of raw materials and products. |

Mitigate risk impacts |

1. Monitor logistics operational variations and relevant response strategies. |

| Corporate Governance | Sustainability | The increase in minimum wages, rising labor insurance rates, continuous electricity price hikes, and overall inflation make an uptrend in production costs inevitable, which will consequently impact our costs and profitability. |

Mitigate risk impacts |

In response to a series of impacts including labor shortages, inflation, rising wages, increased insurance rates, and elevated production costs, the company has implemented the following controllable measures to ensure long-term competitiveness and the interests of our stakeholders. 1. Continuously invest in advanced technologies and new product development to enhance product advantages, optimize manufacturing costs, and adjust our product portfolio and profit structure. This strategy aims to prevent rising costs of existing products from negatively impacting overall sales and eroding profitability. 2. Sustainably drive the application of digitalization and automation, utilizing Artificial Intelligence (AI) and digital technology to elevate productivity per person, minimize inefficiency and waste, and thus mitigate the impact of external cost increases. |

| Corporate Governance |

Sustainability |

Cross-industry competition from MEMS oscillators has resulted in new products entering practical applications, gradually eroding market share and leading to the substitution of some mid-to-high frequency quartz components in communications, thereby lowering market demand. |

Mitigate risk impacts |

1. The R&D unit is shortening the established development timeline for new MEMS oscillator products, accelerating customer validation and mass production rollout. 2. Continuously introduce technical professionals to enhance and expand key technology development efforts. |